CORROSIVE CHEMICAL TRANSFER HOSE – COMPOTEC PTFE 300

COMPOTEC® PTFE is a composite hose consisting of an inner virgin pure PTFE core, reinforced with many other layers, such as thermoplastic films and polypropylene, polyethylene and polyester based fabrics. All layers are overlapped to form a strong but flexible structure, locked between inner and outer steel spiral wires.

As an external cover, a special Polyvinylchloride coated fabric is used for the purpose of protection and identification. It’s resistant to atmospheric agent and abrasion. All the different layers are positively grounded by the metallic reinforcing spirals and, subsequently, compressed between two spirals, one internal and one external.

The chemical design of COMPOTEC® hoses, lightness, flexibility and the ability to operate at certain pressures and temperatures that fully satisfy the requirements of the chemical industry and related transports, like truck rubbers or railway tanks.

FEATURES & APPLICATIONS – COMPOTEC® PTFE is manufactured in accordance with the standard EN 13765:2018 (BS 5842:1980) and the guidelines NAHAD 600/2005. Extremely flexible and easy to handle, COMPOTEC® PTFE is generally used for the transfer of aggressive and corrosive chemical products, under pressure or suction. It is also used in Outdoor or Indoor application, for the transfer from tank trucks, rail trucks, loading or unloading of ships and to pumps and process machinery. Suitable for any chemical product, thanks to the PTFE chemical inertness. All the hoses are 100% resistant to aromatics and can be used both for suction & delivery. Vacuum rating is 0.9 bar, according to the EN ISO 7233 standard. COMPOTEC® PTFE hose’s assemblies are fitted with a complete range of couplings readily available, externally swaged with crimping ferrules in Stainless or Galvanised Steel.

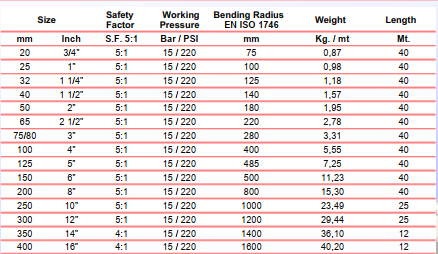

SAFETY SPECIFICATIONS – COMPOTEC® PTFE hoses have a 5 : 1 Safety Factor and they are tested at 1.5 times working pressure, in accordance with the construction standards and the Directive CE PED 2014/68/EU.

The hose is permanently marked on the external tape in compliance with Directive CE PED 2014/68/EU. The hose is supplied with a Declaration of Conformity and Use and Maintenance Manual. Additional test certifications can be supplied upon request. The burst pressure is identified and indicated on the test certificate in accordance with EN 13765:2018. They are manufactured in accordance with the requirements of Par. 2.12 and 3.7 of the Chemical Carrier Code and the “Type Approved by Lloyd’s Register Certification” n° 13/00002/E1.

Electrical continuity is achieved by ties wires bonded to end fittings and furnishes and this system helps to dissipate the electrostatic charges accumulated. The electrical resistance of assembled hoses, is less than 100 Ohm, as required by EN ISO 8031:2020. A B on request it is possible to supply hoses in accordance with the Directive 2014/34/EU ATEX, with special black antistatic conductive external cover, for the grounding cable, and the related documentation.

RANGE:

PTFE 300 HD – HEAVY DUTY

Heavy Duty construction, for the transfer of a wide range of aggressive chemical products under suction or pressure, widely used for many applications. Those used for ship to shore, ship to ship and tank transfer, rail and road tanker loading and unloading. Industrial and Marine applications which require higher operating pressures and full vacuum. Available in 40 mt coils from 3/4” to 8”, 25 mt length up to 12” and 12 mt up to 16”.

PTFE SD – STANDARD DUTY

Flexible hose for standard duties; suitable for the safe transfer of a wide variety of aggressive chemicals, under suction or pressure. Commonly used for loading and unloading of road and rail tankers, storage tank and in-plant applications. Ideal for all process fluids, easy to wash and sterilize with steam. Available in 40 mt coils from 1/2” up to 8”.

View more products: FOOD GRADE RUBBER HOSE

Tiếng Việt

Tiếng Việt